CENTRIFUGAL PARTITION CHROMATOGRAPHY

Centrifugal Partition Chromatography (CPC) is an advanced liquid-liquid separation technique, distinguished by its absence of solid stationary phases. This key feature provides significant advantages over conventional chromatography methods, including enhanced selectivity, seamless scalability from analytical to industrial applications, and reduced solvent consumption, making CPC a more environmentally sustainable purification approach.

Our laboratory is equipped with multiple Kromaton CPC units (Rousselet Robatel, France). The large volume rotor with optimized cell design ensures exceptional loading capacity and resolution for efficient compound purification.

Benefits of Centrifugal Partition CHromatography

Method Scalability

A CPC method designed on an analytical-scale CPC can be linearly scaled to a 10-liter pilot-scale CPC without a loss of resolution. Oftentimes, the hydrodynamic properties allow for faster processing times and flowrates as the methods scale up.

Loading Capacity

CPC offers a higher loading capacity than many solid, stationary phases. For example, a CPC unit with a 1-liter rotor can handle up to fifty grams of a sample per run, equating to 25 grams of sample per liter.

Flexible Selectivity

In addition to a large range in selectivity based on solvent system composition, CPC can operate in different modes utilizing different chemical properties. For instance, pH-zone refining separates compounds based on pKa, making it well suited for ionic compounds.

How does it work?

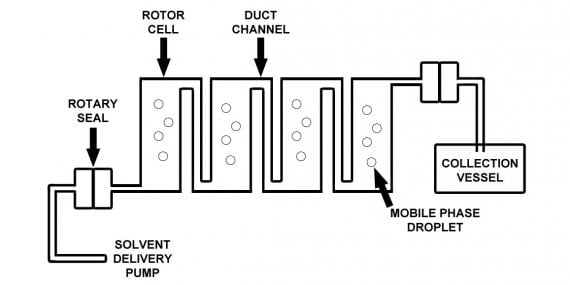

Centrifugal Partition Chromatography (CPC) is a liquid-liquid separation technique that leverages a biphasic solvent system formed by two immiscible liquid phases. Compounds are separated based on their partition coefficients, which determine their distribution between the stationary and mobile phases. The stationary phase is immobilized within the rotor by centrifugal force, while the mobile phase continuously elutes the target compounds through the system.

Although structurally similar compounds may have comparable partition coefficients, CPC amplifies subtle differences by passing the sample through hundreds of interconnected cells, effectively repeating the partitioning process multiple times. Optimization relies on tailored solvent systems, adjusted for specific applications by modifying solvents and their ratios.

With multiple modes of operation, CPC offers exceptional versatility, enabling precise selectivity and making it one of the most powerful tools in separation sciences.

Technology Supplement

Efficient, baseline separation of pyrethrins by Centrifugal Partition Chromatography

ABSTRACT: Pyrethrins are natural pesticides present in the oil extracted from the flowers of Chrysanthemum cinerariaefolium. They are potent ion-channel neurotoxins which have higher selective toxicity for insects compared to mammals. These phytochemicals have an exceptionally safe environmental profile and are an attractive natural alternative to organophosphate insecticides currently used in agriculture. The oil extract contains six pyrethrins compounds, which are structurally related esters. Isolation of reference standards for pyrethrins and their derivatives in multi-gram quantities is a prerequisite for studying toxicity and soil degradation for these natural pyrethrins. Chromatography is difficult because of the high hydrophobicity and close structural similarity. The isolated pyrethrin compounds also have poor stability because they are photosensitive. To facilitate these studies, we have developed a twostep purification process, in which the two groups were first separated by normal phase liquid chromatography on silica gel.

Frequently Asked Questions

As far as the kind of solvents, it is really up to you and your experimentation! We regularly use solvent systems based on hexane : ethyl acetate : methanol: water. However, any mixture of immiscible solvents may be utilized. CPC utilizes significantly less solvent versus traditional solid phase chromatography.

Yes! We routinely use CPC for the separation of extremely polar targets. For example, a polar biphasic solvent system may simply be composed of butanol and water.

Yes! A solvent system composed of hexane : ethyl acetate : water will offer low polarity for those nonpolar separations.

Yes! One of the modes of CPC is pH-zone refining, which exploits differences in pKa to separate compounds by switching the selectivity of the targets between the stationary and mobile phases through the addition of an acid or base. The elution rate of compounds in this mode is dependent on the concentration of the pH-modifier in the mobile phase.

No. CPC is a liquid-liquid extraction technique; you never have to purchase, replace, or recondition any solid stationary phases. CPC also exhibits decreased solvent usage because of high resolution, unique selectivity, and a large loading capacity. This creates an economical, cost-effective approach to your separations!

100%! There is no irreversible adsorption or sample loss that is commonly observed with solid phases. There is also no degradation of labile compounds by the free silanols that are found in silica-based phases, thereby increasing yields and preserving precious material.